| Sign In | Join Free | My frbiz.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My frbiz.com |

|

Brand Name : XWT

Place of Origin : China

MOQ : 1 set

Price : Negotiable

Supply Ability : 25 to 30 sets / Month

Delivery Time : 30 - 45 work days

Packaging Details : Carton , wooden case

Certification : ISO 9001:2008

Model Number : customized parts

Payment Terms : T/T

Item : Deep drawing mold

Material : SKD11, SKH-9, 50# steel , 45# steel , tungsten carbide

Mold lead time : 30 to 45 days in general

Trade term : EXW, FOB, CIF in general

Certificate : ISO 9001:2008

Span life : 1 million to 50 million hits base on different material

Mold cost : Can be returned back if making mass production in xinwangtai

Samples : supply for free

| Product name | Stamping deep drawing mold |

| Type | Progressive die |

| mold design | OEM service, custom services |

| mold insert,punch material | SKD11,SKH-9, ASP23, Tungsten carbide |

| Shipping terms | Express,Sea,Air |

| Port | Shenzhen |

| Working experience | 14 years |

| Size: | According to your drawing |

| Color, Quantity, Unit price, Tooling cost, Tooling size: | To be discussed |

| Surface Finish: | Texture (MT standard), high gloss polishing |

| Mould Life: | 1,000 to 1,000,000 shots |

| (according to your working environment) | |

| Design & Program Softwares: | CAD, CAM, CAE, Pro-E, Solid works…etc. |

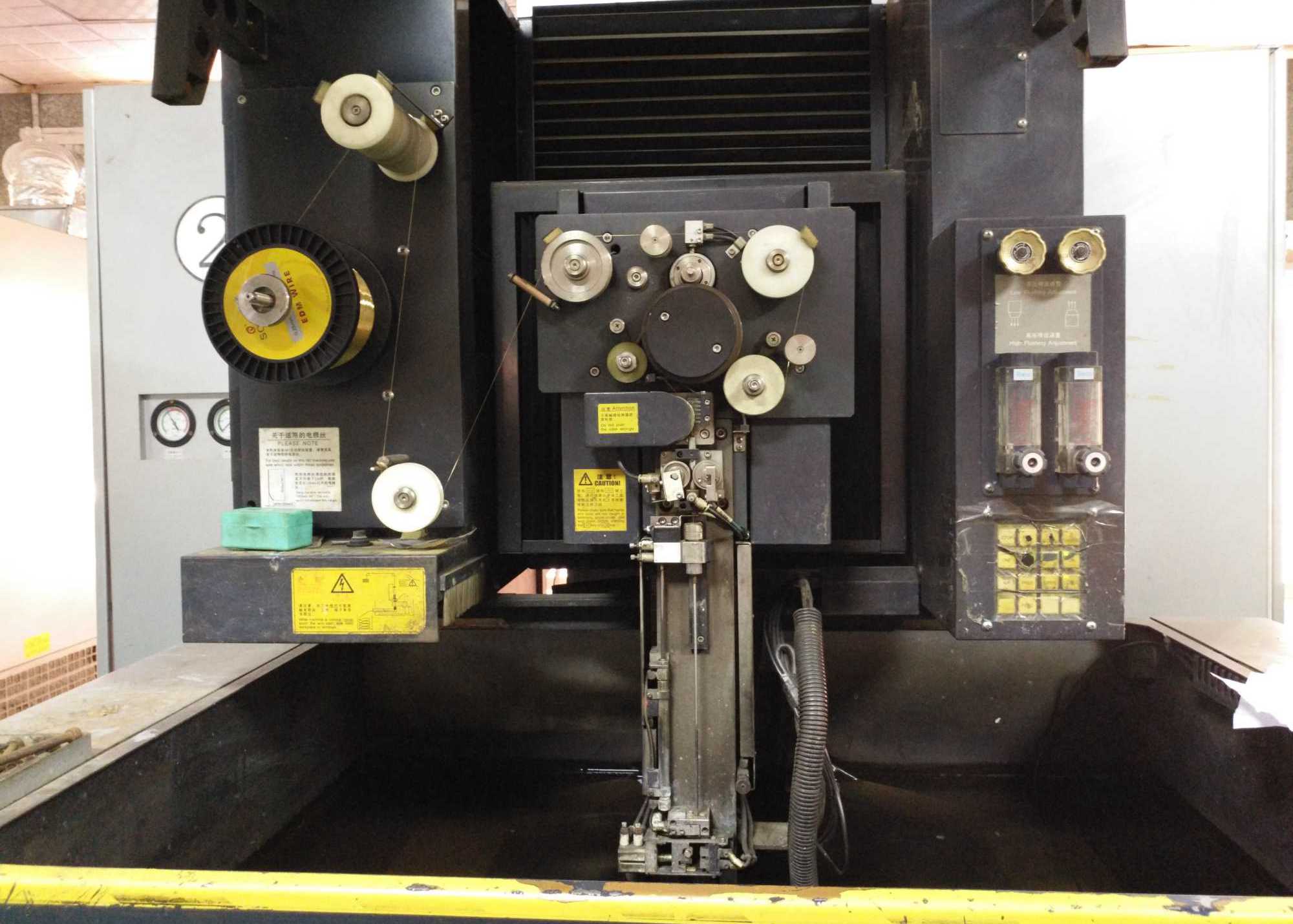

| Equipments: | EDM, Wire Cutting, Grinder, lathe, drilling/milling, high speed press machine 25-200T etc. |

| Package: | Standard exported wooden box packed, or as required |

| Mold building lead time: | T1, 20~50 days, parts measurement report (PPAP supplied). |

| Annual production: | 250 sets of mold |

Company intruduction

1. ODM&OEM service are all welcomed

2. Practicable Software: Solidworks,Pro/Engineer,Auto CAD,PDF,JPG

3. Small orders accept

4. Reasonable and competitive price according to your drawings

Shenzhen Xinwangtai Precision Mould Products Co., Ltd. is an ISO 9001:2008 certified Manufacturer and Supplier of metal stamping tools, and stamping parts, Our main production scope is kinds of deep drawing stamping molds making and deep drawing parts manufacture.

With the support of hardworking and rich-experienced engineers, we are excellent at customizing the molds and parts as you required. Along with these, we also undertake design & development work of press tools, fixtures & gauges and re-engineering & prototype development.

Welcome to sending us your drawing for inquiry, we'll offer our best price in high quality.

Slow speed wire-cutting process

FAQ

1. Q: Are you a factory or trading company?

A: We are a factory,There are 4,000 square meters of manufacturing plants and RD bases in our factory.

2. Q: What products do you supply?

A: we are specialized in stamping progressive die and stamping parts, deep drawing parts is our main range.

3. Q: Where is your factory located? How can I visit there?

A: Our factory is located in Shajing Baoan Shenzhen City, Guangdong Province, China,We warmly welcome all our clients, from home or abroad, to visit us!

4. Q: What is the material of your molds?

A: The material are DC53,SKD11,D2,SKH-9,SKH-51 ,ASP-23, Tungsten steel.

5. Q: What the press your fatory have ?

A: There are 30T,60T,110T,160T, 200T press machines in our factory.

|

|

Deep drawing die making of sheet metal deep drawn parts metal working Images |